What Affect the Cleaning Efficiency of Lint Cleaner

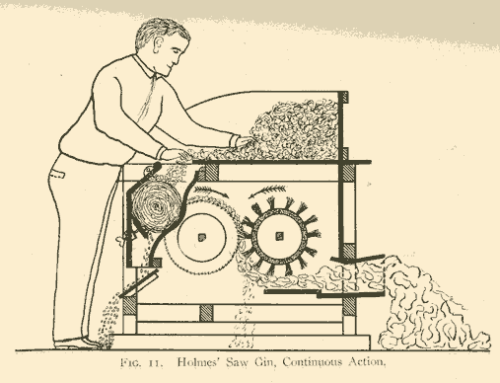

Saw-type lint cleaner is used for cleaning the impurities contained in lint cotton so as to improve the outside look and inner quality of lint cotton. This machine adopts advanced technology and has high cleaning efficiency. In the actual operation process, there are some factors that may affect its cleaning efficiency.

Moisture Regain of Lint Cotton

The appropriate moisture regain of lint cotton is about 6.38%-9.89%. The higher moisture regains of lint, the worse elasticity of cotton fiber. This kind of lint cotton is easy to deform, and the impurities are difficult to be removed. Besides, the worse carding effect may lead to the blockage of lint cleaner. Conversely, low moisture regain makes the cotton fiber fluffy, improving the carding effect. However, the strength of fiber becomes relatively weak, easily leading to breakage and damage to fiber.

The thickness of Cotton Layer

The thickness of the cotton layer is consistent with productivity. Generally, the larger productivity, the thicker cotton layer and the larger quantity of cotton fiber that saw tooth have to deal with. So impurities would easily wrap in fiber and become hard to be removed. On the contrary, a thin cotton layer makes the impurities easy to be removed. Therefore, the yield of cotton gin should not be too high, or the lint cleaner will be easily blocked, leading to a poor cleaning effect.

Pressure on Feed Roller and the Space between Feed Roller and Feed Plate

The pressure on the feed roller and the space between the feed roller and feed plate directly influence the carding effect of saw tooth to cotton fiber. Generally, high pressure and small space contribute to a good clamping effect to the cotton fiber, ensuring fully carding. However, too high pressure and too small space make the lint easy to be blocked when sudden increase the lint quantity.

Installation Position, Angle and Quantity of Cleaning Bar

The installation position of the cleaning bar refers to the spacing between the knife edge of the cleaning bar and sawtooth, and the distance between the cleaning bar and feed plate. In general, the smaller spacing between the cleaning bar and sawtooth, the farther distance from the feeding plate, and the impurities are easier to be removed under the effect of centrifugal force. However, the too-small spacing would cut off fiber and cause damage to the cleaner.

The installation angle of the cleaning bar usually refers to the angle between the working surface of the cleaning bar and the tangent line of the saw tooth at this point. The bigger angle, the easier discharge of impurities.

The greater number of cleaning bars, the easier removal of impurities. However, the fiber is also easy to be discharged. The number of cleaning bars is decided according to the specific situations, general take 5-6 cleaning bars as proper.

Perfectness Ratio of Saw Tooth

Sawtooth is important to lint cleaner. If the sawtooth is in perfect condition, then it has a perfect dealing effect on fiber and a higher impurity cleaning ratio. Therefore, we should strengthen the maintenance work of saw tooth during the processing, ensuring normal operation condition of lint cleaner.

Design and Manufacture of Air System

Uneven distribution of lint cotton on cotton collecting dust cage would appear due to the following reasons: improper piping layout of the air system, unreasonable selection of draught fan, poor or uneven ventilation, etc. All these problems would affect the impurity removing ratio and cause machine-blocking problems.