Cotton plays a significant role in human social life, however, cotton can be a very labor-intensive crop, which includes the planting and harvesting process. After wheat and crop combines have developed, the demand for cotton pickers increased.

Cotton Characteristics Make it Hard to Harvest

Cotton is an extremely labor-intensive crop, and this can be one reason that slavery existed. Even within the same field, cotton bolls on the plants would become ready for harvesting at a different rate. The mature bolls could not leave on the plants until all have matured because the mature cotton quality would deteriorate if the bolls opened, so pickers need to harvest ripe cotton bolls and at the same time leave unripe cotton on the plant. So traditionally, cotton was picked by hand, pickers have to come back three or four times each harvest period.

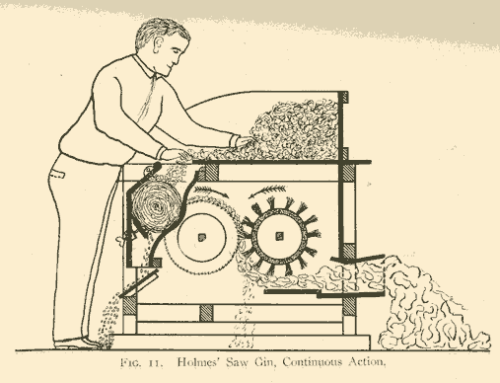

Early Cotton Harvesting Machine

In 1850 the first cotton harvesting machine was patented. Then over the next century, over 1800 patents were issued for cotton harvesting schemes. Some early prototypes tried to harvest with pneumatic mechanisms, some tried to adopt threshing machines, others tried static electricity or mechanical fingers. However, these prototypes make second passing through the field impossible for the damage to cotton.

The function of The Spindle Mechanism

The most successful prototype was the spindle mechanism. This machine can pass through cotton over a series of spindles which were turning at high speed. Open boll would wrap around the spindle when passing. Then spindle would move around to a doffer where the spindle would rotate in the opposite direction and the doffer would pull the fibers off to be cleaned and transported to a hopper. But spindle could not capture enough fibers.

Successful Cotton Harvester Invented by International Harvester

Engineer John D. Rust remembered that when he was a kid, dew made cotton stick to his fingers, and his grandmother wetted the spindle on the spinning wheel to let cotton adhere. Then he created a machine that add water to spindles. This method was adopted by International Harvester and was invented successfully harvester in 1942. However, for the restriction on steel, the cotton combine could not get quantity production until 1948. By then, they have made an updated model.

High Efficiency

At that time, hybrid varieties which produce bolls that were higher off the ground and varieties that ripened uniformly were developed, together with the appearance of herbicides making cotton-picking greatly labor-saving. For example, cotton picking from 125 hours per acre was reduced to 25.